Difference between revisions of "Engine"

(→I-6) |

|||

| Line 53: | Line 53: | ||

The last automotive use of the Chrysler flathead inline-six was in 1960. It was replaced by the much more efficient [[overhead valve engine|OHV]] Slant-6 the following year, which appeared in most Dodge trucks starting in 1961. The flathead remained in production until the early 1970s for industrial and agricultural use. | The last automotive use of the Chrysler flathead inline-six was in 1960. It was replaced by the much more efficient [[overhead valve engine|OHV]] Slant-6 the following year, which appeared in most Dodge trucks starting in 1961. The flathead remained in production until the early 1970s for industrial and agricultural use. | ||

| + | |||

| + | [[File:Flathead6.png|600px|center]] | ||

===== Slant 6 ===== | ===== Slant 6 ===== | ||

Revision as of 02:32, 9 April 2020

Automotive Engine, Internal Combustion Engine (ICE) and Petro Engine

Contents

Definition

An internal combustion engine (ICE) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is applied typically to pistons, turbine blades, rotor or a nozzle. This force moves the component over a distance, transforming chemical energy into useful work.

The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860 and the first modern internal combustion engine was created in 1876 by Nikolaus Otto (see Otto engine).

The term internal combustion engine usually refers to an engine in which combustion is intermittent, such as the more familiar four-stroke and two-stroke piston engines, along with variants, such as the six-stroke piston engine and the Wankel rotary engine. A second class of internal combustion engines use continuous combustion: gas turbines, jet engines and most rocket engines, each of which are internal combustion engines on the same principle as previously described. Firearms are also a form of internal combustion engine.

In contrast, in external combustion engines, such as steam or Stirling engines, energy is delivered to a working fluid not consisting of, mixed with, or contaminated by combustion products. Working fluids can be air, hot water, pressurized water or even liquid sodium, heated in a boiler. ICEs are usually powered by energy-dense fuels such as gasoline or diesel fuel, liquids derived from fossil fuels. While there are many stationary applications, most ICEs are used in mobile applications and are the dominant power supply for vehicles such as cars, aircraft, and boats.

Typically an ICE is fed with fossil fuels like natural gas or petroleum products such as gasoline, diesel fuel or fuel oil. There is a growing usage of renewable fuels like [[biodiesel] for CI (compression ignition) engines and bioethanol or methanol for SI (spark ignition) engines. Hydrogen is sometimes used, and can be obtained from either fossil fuels or renewable energy.

History

In the early years, steam engines and electric motors were tried, but with limited success. In the 20th century, the internal combustion (ic) engine became dominant. In 2020, the internal combustion engine remains the most widely used but a resurgence of electricity seems likely because of increasing concern about ic engine exhaust gas emissions.

As of 2020, the majority of the cars in the United States are gasoline powered. In the early 1900s, the internal combustion engines faced competition from steam and electric engines. The internal combustion engines of the time was powered by gasoline. Internal combustion engines function with the concept of a piston being pushed by the pressure of a certain explosion. This explosion is burning the hydrocarbon within the cylinder head an engine. Out of all the cars manufactured during the time, only around one fourth are actually considered internal combustion. Within the next couple of years, the internal combustion engine came out to become the most popular automotive engine. Sometime within the 19th century, Rudolf Diesel invented a new form of internal combustion power, using a concept of injecting liquid fuel into air heated solely by compression. This is the predecessor to the modern diesel engine used in automobiles, but more specifically, heavy duty vehicles such as semi-trucks.

Internal combustion engines

Petrol engines quickly became the choice of manufacturers and consumers alike. Despite the rough start, noisy and dirty engine, and the difficult gear shifting, new technologies such as the production line and the advancement of the engine allowed the standard production of the gas automobiles. This is the start, from the invention of the gas automobile in 1876, to the beginning of mass production in the 1890s. Henry Ford's Model T drove down the price of cars to a more affordable price. At the same time, Charles Kettering invented an electric starter, allowing the car to be more efficient than the mechanical starter. The abundance of fuel propelled gas automobiles to be the highly capable and affordable. The demand of gasoline rose from 3 billion barrels in 1919 to around 15 billion in 1929.

An internal combustion engine is a motor that is powered by the expansion of gas which is created by the combustion of hydrocarbon gases fuels. To elaborate, an internal combustion used the heat of a combustion created by the injected hydrocarbon fuel to create mechanical motion. At the time of the early 1900s, wood alcohol was a popular fuel for French and German automobiles, but as governments imposed large taxes on the production, the price of wood alcohol rose above that of gasoline. Gasoline engines became popular as a result of this, as internal combustion engines were commonly known as gasoline engines. Although gasoline engines became popular, they were not particularly desirable due to the dangers of fuel leaks that may cause explosions. Therefore, many inventors attempted to create a kerosene burning engine as a result. This was not a successful venture applying it for automotive usage. There are many different types of fuels for internal combustion engines. These include diesel, gasoline, and ethanol.

Also See

Mopar Engines

4 Cylinder

Straight-4

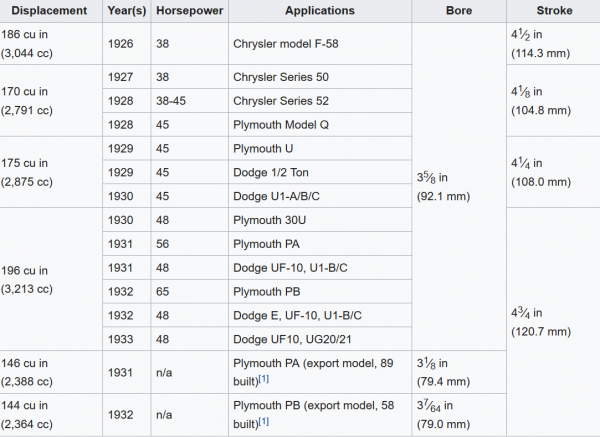

Chrysler introduced a straight-four derivative of their new Flathead straight-six]] in 1926. Initially used by Chrysler, the straight-four was fitted to Plymouth and Dodge light trucks beginning in 1929, lasting in production through 1933.

The original version displaced 185.8 cid and produced 38 hp. This was only produced in 1926, with displacement reduced to 170.3 cid for 1927 and 1928. Power was initially rated the same but was upped to 45 hp during the 1928 model year.

After the introduction of the Plymouth brand in 1929, the base engine was enlarged to 175.4 cid with the power rating remaining the same. It also equipped Dodge light trucks in 1929–1930. It was enlarged again to 196.1 cid in 1930 with 48 hp. The engine was slightly revised for 1931 with 56 hp and 1932 with 65 hp for Plymouth only, Dodge continued with the 48 hp from 1931 to 1933. A small-bore version was developed for export markets in 1931, with a narrower bore which brought the RAC rating down from 21 to 15.6 hp. For 1932 the bore was made a little slimmer yet, bringing the tax horsepower rating to just under 15.5.

6 Cylinder

Flathead 6

There were essentially two lines of flathead inline-sixes made by the Chrysler Corporation. Chrysler and DeSoto used a longer 25 inch block with greater cylinder spacing, while Dodge and Plymouth shared a 23 inch block. There is one exception to this: when Chrysler established an engine foundry in Windsor, Canada in 1938, it was decided to only use the long block for all Canadian-built engines. These engines received a trailing "C" in their designation, becoming P8C for example. Thanks to judicious dimensioning, the Canadian 201- and 218-cubic inch engines had nearly identical displacement to their American cousins.

Beginning in 1938, the 201.33 cid inline-six was also used in Massey Harris's Model 101 (later known as the 101 Super). It continued to be used by Massey Tractors until 1940, when it was supplanted by the 217.76 cid which lasted until 1942.

The last automotive use of the Chrysler flathead inline-six was in 1960. It was replaced by the much more efficient OHV Slant-6 the following year, which appeared in most Dodge trucks starting in 1961. The flathead remained in production until the early 1970s for industrial and agricultural use.

Slant 6

V-6

I-8

Early V-8

Small Block

Poly

LA

Magnum

Gen 1 Hemi

Wedge Big Block

The Chrysler B and RB engines are a series of big-block V8 gasoline engines introduced in 1958 to replace the Chrysler FirePower (first generation Hemi) engines. The B and RB engines are often referred to as "wedge" engines because they use wedge-shaped combustion chambers; this differentiates them from Chrysler's 426 Hemi big block engines that are typically referred to as "Hemi" or "426 Hemi" due to their hemispherical shaped combustion chambers.

Design features of the B and RB engines include 17 capscrews per cylinder head, a cylinder block that extends 3 in (76.2 mm) below the crankshaft centerline, an intake manifold not exposed to crankcase oil on the underside, stamped-steel shaft-mounted rocker arms (race versions used forged steel rockers), and a front-mounted external oil pump driven by the camshaft.

The 'B' series wedge engine was introduced in 1958 with 350 cu in (5.7 L) and 361 cu in (5.9 L) versions. The 361 would continue in production until the end of the series, albeit only for truck installation. The RB ("raised B") arrived one year after the launch of the B series engines, in 383 cu in (6.3 L) and 413 cu in (6.8 L) displacements. Unlike the previous B-engines, which had a 3 3⁄8-inch (85.7 mm) stroke, the RB engines had a 3 3⁄4-inch (95.3 mm) stroke.

For 1960, a "ram induction" system increased the 413's torque up to 495 lb⋅ft (671 N⋅m) on the Chrysler 300F versions.

The last 'B-RB' wedge-headed engine was produced in August 1978, ending the era of Chrysler "big-block" engines.

B-Engine

350

The 350 cu in (5.7 L) B engine was, along with the 361, the first production B engine, first available in 1958. It had a bore of 4.06 in (103 mm). The 350 is classified as a big block engine. All parts except for the pistons are fully compatible with the 361.

Vehicles using the B 350:

- 1958 DeSoto Firesweep

- 1958 Dodge

- 1958 Plymouth Fury

361

The 361 cu in B engine also introduced in 1958 was essentially the same as the 350 except with a larger 4 1⁄8-inch (104.8 mm) bore, for an actual displacement of 360.83 cu in (5,913 cc). In 1962, the Dodge Polara 500 came standard with a 305 bhp (227 kW) version of the 361 that had a four-barrel carburetor, dual-point distributor, and dual exhausts. Plymouth called their versions of the early B engine the Commando, variants of which included the Golden Commando and Sonoramic Commando. It produced 305 bhp (227 kW). DeSoto's B engine was named Turboflash and produced 295 bhp (220 kW). The Dodge standard version was a 2-barrel with 295 bhp (220 kW) called the Super Red Ram with an optional variant that was called the D500 and produced 320 bhp (239 kW).

The 361 would last until the end of the series, albeit for trucks only. In its early years, the 305-horsepower 361 was optional on many vehicles, and standard on, among others, the Dodge 880. The 361 had a fuel injected version in 1958 only.[1] Very few of the fuel injected B engines were made and only a handful remain, since most were brought back to the dealer to be fitted with carburetors.

383

The 383 cu in B engine — not to be confused with the RB version — was essentially a larger bore version of the 350 and 361, using a 4.25 in (108.0 mm) bore for a 383.03 cu in (6,277 cc) displacement. This venerable engine was introduced in 1959. Dodge's version, the D500 had a cross-ram induction manifold and dual 4-barrel carburetors as options. In some Dodge applications, this engine was labeled as the Magnum, while the Plymouth's version was called the Golden Commando. Both came with a dual point distributor in high-performance versions.

The 383 became the standard model Mopar performance engine for the next decade. The big bore allowed for larger 2.08 in (53 mm) intake valves, and the relatively short stroke helped it to be a free-revving engine, as well as a free-breathing one.

Producing a maximum of 330 hp (246 kW; 335 PS) (gross) and 460 lb⋅ft (624 N⋅m) of torque for the 1960 model year, the 383 beat the 392 Hemi that had reached 435 lb⋅ft (590 N⋅m). The 1960 383 engines featured the same basic ram induction system as the Chrysler 300F's 413 RB engines (named Sonoramic Commando when sold in Plymouth form). The later 383 Magnum (starting in 1968) used the 440 Magnum heads, camshaft, and exhaust manifolds. This engine was advertised at 335 hp (250 kW; 340 PS).

400

The 400 cu in (6.6 L) B engine was introduced in 1972 to replace the venerable 383, and were power-rated via the net (installed) method. Chrysler increased the bore size of the 383 to create the 400. Its bore of 4.342-inch (110.3 mm) was the largest used in any production Chrysler V8 at the date of its introduction. All parts except for the pistons were interchangeable between the 383 and 400.

Crankshafts were of cast iron composition. Three versions of this engine were available: a two-barrel/single exhaust version producing 170 hp (127 kW; 172 PS) at 4,400 rpm with 305 lb⋅ft (414 N⋅m) of torque at 2,400 rpm, a four-barrel/single exhaust version producing 205 hp (153 kW; 208 PS) at 4,400 rpm, and a high performance four-barrel/dual exhaust version rated at 260 hp (194 kW; 264 PS) at 4,800 rpm, 410 lb⋅ft (556 N⋅m) of torque at 3,200 rpm. All three versions used the same 8.2:1 compression ratio. The 400 was used in car, truck, and motorhome chassis. Horsepower and torque ratings gradually declined through the years due to the addition of more federally mandated emissions controls, until all Chrysler passenger vehicle big-block production ceased in 1978. For its last year of production, it only produced 190 hp (142 kW) (although a heavy-duty version was also available).

Due to its large factory bore size, short (compared to RB engines) deck height, and bottom end strength that is greater than any other production B or RB engine due to extra material added around the main bearing caps, 400 B engine blocks have become a popular choice for high-performance engine build ups.

RB-Engine

The RB engines, produced from 1959 to 1979, are Raised-Block (taller) versions of the B engines. All RB engines have a 3 3⁄4 in (95.3 mm) stroke, with the bore being the defining factor in engine size. All RB wedge engines share a deck height of 10.725 in (272.4 mm), and were fitted with 6.768 in (171.9 mm) long connecting rods, resulting in a 1.80:1 rod ratio. Bore center distance is 4.8 in (120 mm). All RBs are oversquare.

383

Not to be confused with the 383 B engine, the 383 RB had a 4 1⁄32-inch (102.4 mm) bore (with the long stroke of 3 3⁄4-inch (95.3 mm)) for a displacement of 383 cu in (6.3 L). It was only available in 1959 and 1960 on the US-built Chrysler Windsors and Saratogas; one of Trenton Engine's lines had been converted to the new RB engine (to make the 413), and demand for the 383 B engine was too high for the remaining line. The solution was to create a 383 RB to fill the gap until the plant figured out how to quickly switch from one block to the other.

413

Not to be confused with the 383 B engine, the 383 RB had a 4 1⁄32-inch (102.4 mm) bore (with the long stroke of 3 3⁄4-inch (95.3 mm)) for a displacement of 383 cu in (6.3 L). It was only available in 1959 and 1960 on the US-built Chrysler Windsors and Saratogas; one of Trenton Engine's lines had been converted to the new RB engine (to make the 413), and demand for the 383 B engine was too high for the remaining line. The solution was to create a 383 RB to fill the gap until the plant figured out how to quickly switch from one block to the other.

| Model years | Fuel system | Power | Torque | Compression ratio |

|---|---|---|---|---|

| 1959–1961 | 4-Barrel Carburetor | 340 hp (254 kW) at 4600 rpm | 480 lb⋅ft (651 N⋅m) at 2800 rpm | 10.0:1 |

| 1959 | 2 × 4-Barrel Carbs | 380 hp (283 kW) at 5000 rpm | 525 lb⋅ft (712 N⋅m) at 3600 rpm | |

| 1960–1961 | 375 hp (280 kW) at 5000 rpm | 525 lb⋅ft (712 N⋅m) at 2800 rpm | ||

| 1962-1965 | 4-Barrel Carb | 340 hp (254 kW) at 4600 rpm | 480 lb⋅ft (651 N⋅m) at 2800 rpm | 10.1:1 |

| 1962 | 2 × 4-Barrel Carbs | 380 hp (283 kW) at 5000 rpm | 480 lb⋅ft (651 N⋅m) at 2800 rpm | |

| 1963-1965 | 4-Barrel Carb | 360 hp (268 kW) at 4600 rpm | 495 lb⋅ft (671 N⋅m) at 2800 rpm | |

| 1963-1964 | 2 × 4-Barrel Carbs | 390 hp (291 kW) at 4800 rpm | 530 lb⋅ft (719 N⋅m) at 3600 rpm |

413 Max Wedge

In 1962, a special version known as the "Max Wedge" was made available for drag racing and street use; this version produced 420 bhp (313 kW) at 5000 rpm.

426

Not to be confused with the 426 Hemi, the 426 cu in (7.0 L) RB was a wedge-head RB block with a 4.25 in (108 mm) bore. The 426 Wedge served as Chrysler's main performance engine until the introduction of the 426 Hemi. It was initially offered as the "non-catalogued" option S42 in Chryslers (the number of such produced is uncertain), offered with 373 or 385 hp (278 or 287 kW) via a single 4-barrel carburetor (11.0:1 or 12.0:1 compression ratio, respectively), or 413 or 421 hp (308 or 314 kW) via ram-inducted dual 4-barrel carburetors (with the same compression ratios). For 1963, horsepower ratings would slightly increase (see below), and it became optional in B-bodied Dodges and Plymouths. After 1963, it would be used only in Dodges and Plymouths.

A 426 Street Wedge block was also available in 1964 and 1965. It bears little relation to the Max Wedge except for basic architecture and dimensions. The Street Wedge was available only in B-body cars (Plymouth and Dodge) and light-duty Dodge D Series trucks. It was an increased-bore version of the standard New Yorker 413 single 4-barrel engine.

426 Max Wedge

The Max Wedge was a race-only version of the 426 Wedge engine offered from the factory. Known as the Super Stock Plymouth and Ramcharger Dodge, the Max Wedge featured high-flow cylinder heads developed through state-of-the-art (at the time) airflow testing.[5] They had 1⅞-inch exhaust valves, which required the cylinder bores to be notched for clearance. The blocks were a special severe-duty casting with larger oil-feed passages than other RB engines, and the blocks were stress-relieved by the factory. Induction came by means of a cross-ram intake manifold tuned for peak power above 4000 rpm and two Carter AFB-3447SA 4-barrel carburetors. The Max Wedge also included high-flow cast-iron exhaust manifolds that, on the later versions, resembled steel tube headers. The Max Wedge was factory rated at 415 or 425 bhp (309 or 317 kW) (depending on compression), and 480 lb⋅ft (651 N⋅m) at 4400 rpm.

Before the end of the 1963 model year, Chrysler introduced the Stage II Max Wedge with improved combustion chamber design and an improved camshaft. The last performance year for the Max Wedge came in 1964 with the Stage III. The factory-advertised power rating never changed despite the Stage II and III improvements.

440

The 440 cu in (7.2 L) RB was produced from 1965 until 1978, making it the last version of the Chrysler RB block. It had a light wall construction, precision cast-iron block, with iron heads and a bore of 4.32 in (109.7 mm), for an overall displacement of 440 cu in (7.2 L).

From 1967 to 1971, the high-performance version was rated at 375 bhp (380 PS; 280 kW) (370 bhp (375 PS; 276 kW) in 1971) at 4,600 rpm and 480 lb⋅ft (651 N⋅m) at 3,200 rpm of torque with a single 4-barrel carburetor, and from 1969 to 1971, the highest-output version had an intake setup with 3X2-barrel Holley carburetors ("440 Six Pack" for Dodge, "440 6-BBL." for Plymouth) producing 390 bhp (395 PS; 291 kW) at 4,700 rpm (385 bhp (390 PS; 287 kW) in '71) and 490 lb⋅ft (664 N⋅m) at 3,200 rpm of torque.

In 1972, changes were made to the horsepower ratings of vehicle engines from gross (engine only, without air cleaner, exhaust system, alternator, or other power-consuming components) to net (with alternator, air cleaner, mufflers, and other vehicle equipment installed). The new rating system produced lower, more realistic numbers for any given engine. At the same time, emissions regulations were demanding cleaner exhaust. Engines including the 440 were made with reduced compression, modified cam timing, and other tuning measures to comply with the newly tightened emissions regulations. The 1972 440 produced 335 bhp (250 kW) (gross) at 4400 rpm; the new net rating was 225 hp (168 kW)—which very closely coincided with period German DIN ratings and TÜV measurements.

The high-output 440 (4-barrel/mild cam/dual exhausts) was marketed as the Magnum in Dodges, the Super Commando in Plymouths, and the TNT in Chryslers. From 1972 to 1974 the engine (detuned to run on lead-free gas) was rated at 280 hp (209 kW) net, and dropped in hp each year until 1978, when it was rated at 255 hp (190 kW) (in police specification) and limited to Chrysler New Yorkers, Chrysler Newports, Dodge Monaco Police Pursuits, and Plymouth Fury Police Pursuits. It was also available in marine and heavy-duty commercial applications until that year.

2nd Generation Hemi

426

V-10

This Wiki is Under Construction, and can use your help!

Please take a moment to add any information you might have on this topic. It is through this type of Member collaboration that the MoparWiki will grow into being the Ultimate Mopar Infobase. The links contained in the Understanding Wikis box in the sidebar can help you get started.

Random Page | Longest Wikis | Oldest Wikis | Newest Images | Newest Wikis | List of Categories | List of Every Freakin Wiki

- Register to Edit

- It takes less than 5 minutes to request registration for editing, and we try to approve within 24 hours. Click the Register Link in the Top Bar.

- MoparWiki Help

- While editing Wikis may at first glance appear a little overwhelming, it really isn't. You will find this site's HELP (link found in the sidebar) to be very strong and easy to understand. The best way to start is with small edits and working on your user page -- and you will become a Pro in no time.

References

This Wiki requires References

The information in this wiki will have more creditability with some references to back it up